Last month, one of our regular customers sent us a quotation list for ASTM A312 TP316L Pipe. This client is a vendor who is specialized in supplying steel materials for various project in Vietnam. This new inquiry is for MULTI-OFFSHORE WIND FARM PROJECT.

As client’s requirements, the end user ask us to provide the technical offer and sample MTC for approve first. It is a complex job due to so many items and various materials and products.To support our good regular client, I work for it in three days, and submitted all the documents and certificates. After two weeks, our client inform us the end user has approved our documents and certificates. We should quote at this stage.

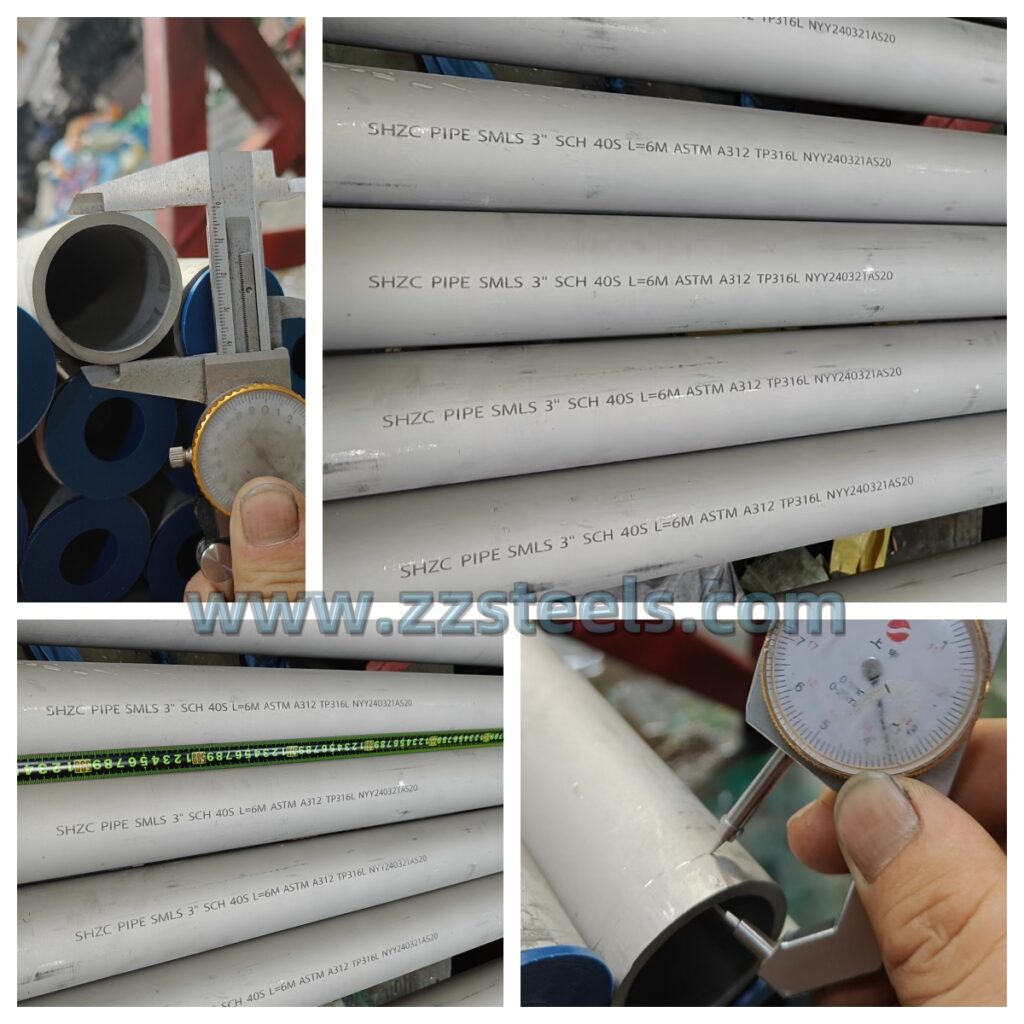

Due to the big amount, both client and us paid more attention for this order, they came to China and visited our factory. They were satisfied with our factory and the materials. We signed the contract after they backed to Vietnam.

| ITEM | Description | Types | Size | Length | Material |

| 1 | Pipe | SMLS | 1/2″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 2 | Pipe | SMLS | 3/4″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 3 | Pipe | SMLS | 1″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 4 | Pipe | SMLS | 1 1/4″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 5 | Pipe | SMLS | 1 1/2″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 6 | Pipe | SMLS | 2″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 7 | Pipe | SMLS | 3″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

| 8 | Pipe | SMLS | 4″ PIPE, SCH.40S | 6m/pcs | ASTM A312 TP316L |

ASTM A312 TP316L Pipe Specification

| Processing Method | Seamless and Welded |

| Size Range | 1/8” – 30” / DN6 – 750 |

| Thickness Schedule | SCH 10S- SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.19 |

| Surface Treatment | Polish , Mirror , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L, S32205, S31803, 32750, 32760, S32550 |

ASTM A312 Standard Scope

This specification covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service.

Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309Cb, TP309S, TP310Cb, TP310S, TP316, TP321, TP347, and TP348, and are intended for service at temperatures where creep and stress rupture properties are important.

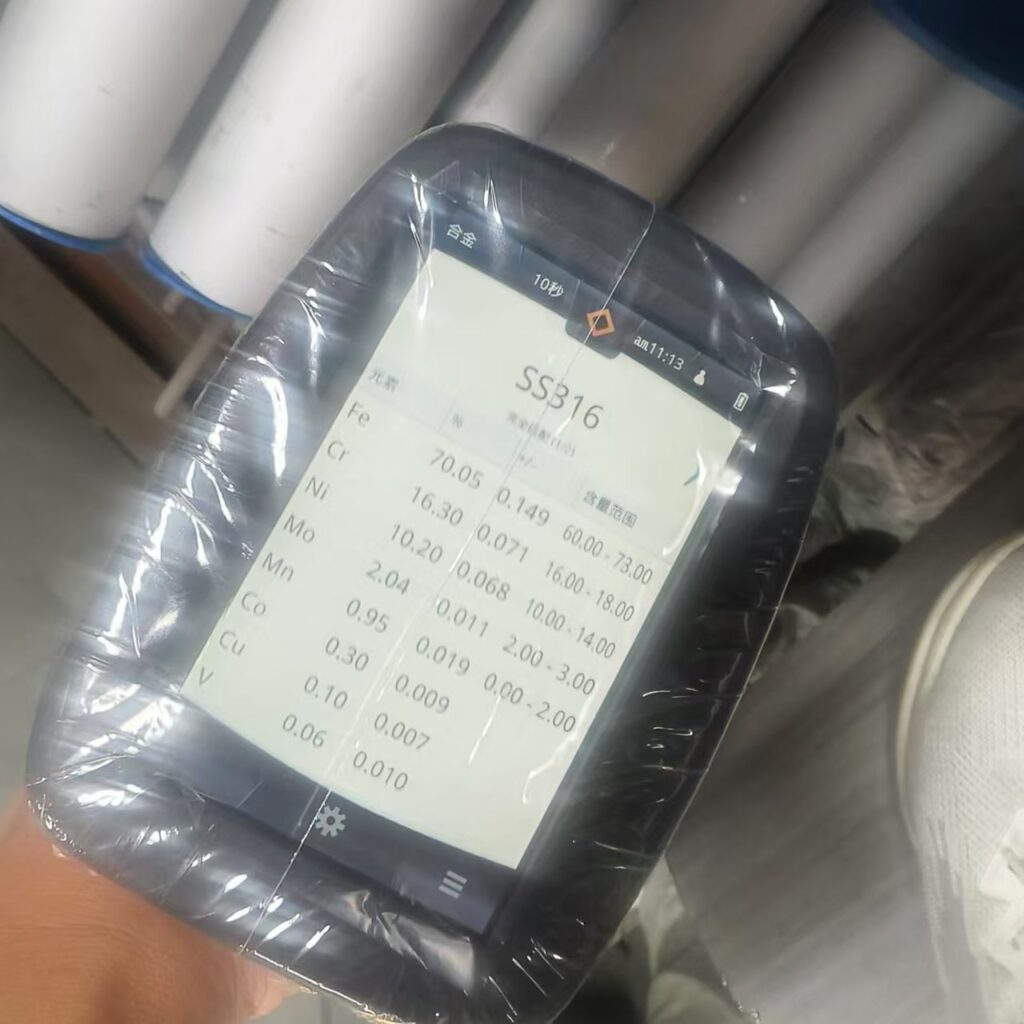

Chemical Composition

The steel shall conform to the requirements as to chemical composition prescribed in Table 1.

Table 1

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A312 TP316 | MIN | 11.00 | 16.00 | 2.00 | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | |

| ASTM A312 TP316L | MIN | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 |

Tensile Requirements

The tensile properties of the material shall conform to the requirements prescribed in Table 2.

Table 2

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A312 TP316 | 515min | 205min | 35 min |

| ASTM A312 TP316L | 485 min | 170 min | 35 min |

Stainless Steel Pipe Dimension

| DN | NPS | OD | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 |

| 6 | 1/8 | 10.3 | 1.24 | – | 1.45 | 1.73 | 1.73 | – | 2.41 | 2.41 |

| 8 | 1/4 | 13.7 | 1.65 | – | 1.85 | 2.24 | 2.24 | – | 3.02 | 3.02 |

| 10 | 3/8 | 17.1 | 1.65 | – | 1.85 | 2.31 | 2.31 | – | 3.20 | 3.20 |

| 15 | 1/2 | 21.3 | 2.11 | – | 2.41 | 2.77 | 2.77 | – | 3.73 | 3.73 |

| 20 | 3/4 | 26.7 | 2.11 | – | 2.41 | 2.87 | 2.87 | – | 3.91 | 3.91 |

| 25 | 1 | 33.4 | 2.77 | – | 2.90 | 3.38 | 3.38 | – | 4.55 | 4.55 |

| 32 | 11/4 | 42.2 | 2.77 | – | 2.97 | 3.56 | 3.56 | – | 4.85 | 4.85 |

| 40 | 11/2 | 48.3 | 2.77 | – | 3.18 | 3.68 | 3.68 | – | 5.08 | 5.08 |

| 50 | 2 | 60.3 | 2.77 | – | 3.18 | 3.91 | 3.91 | – | 5.54 | 5.54 |

| 65 | 21/3 | 73.0 | 3.05 | – | 4.78 | 5.16 | 5.16 | – | 7.01 | 7.01 |

| 80 | 3 | 88.9 | 3.05 | – | 4.78 | 5.49 | 5.49 | – | 7.62 | 7.62 |

| 90 | 31/2 | 101.6 | 3.05 | – | 4.78 | 5.74 | 5.74 | – | 8.08 | 8.08 |

| 100 | 4 | 114.3 | 3.05 | – | 4.78 | 6.02 | 6.02 | – | 8.56 | 8.56 |

How to inspect ASTM A312 TP316L pipe?

Appearance inspection

Dimensional deviation: Check whether the wall thickness, outer diameter, length and other dimensions of the stainless steel pipe meet the standards or contract requirements. You can use tools such as vernier calipers and tape measures to measure.

Surface quality: Check whether there are cracks, pitting, pores, slag inclusions, oxide scale, rust and other defects on the inner and outer surfaces of the stainless steel pipe. The surface of high-quality stainless steel pipes should be smooth and flat without obvious defects.

Welding quality: For welded stainless steel pipes, check the weld formation, size, mechanical properties of the welded joint, etc. The weld should be free of cracks, lack of fusion, pores, slag inclusions and other defects.

Chemical composition inspection

Spectral analysis: The chemical composition of stainless steel pipes is tested by a spectrometer to ensure that they meet the relevant standards or grade requirements. This is an important means of identifying stainless steel materials.

Application Fields

Due to its excellent performance, TP316L stainless steel pipes are widely used in the following fields:

Chemical and pharmaceutical: used for pipelines, equipment and containers for conveying various corrosive media.

Medical equipment: used for manufacturing surgical instruments, implants, etc.

Ship and marine engineering: used for manufacturing ship structures, pipelines and equipment, etc.

Environmental protection engineering: used for sewage treatment equipment, desulfurization equipment, etc.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....